Effective Static Mixers & Mixing Solutions for a wide range of applications including:

- Chlorination & Disinfection

- Coagulation & Flocculation

- Refinery applications

- Food & Beverage

- Mining

- Bioenergy

- Custody Transfer

Materials of Construction:

- Carbon Steel

- Specialty Steels

- PVC/CPVC

- Kynar (PVDF)

- PTFE/PFA

- Polypropylene

- Ductile Iron housing

- Stainless Steels (304, 316L, and higher grades)

- Duplex and Super Duplex material

- Hastelloy (C276 is the most common)

- Epoxy coated or painted steel

- Nickel/Chromium Alloys

Contact our email at

or tel 925 800 1467 for a quotation or to discuss your application.

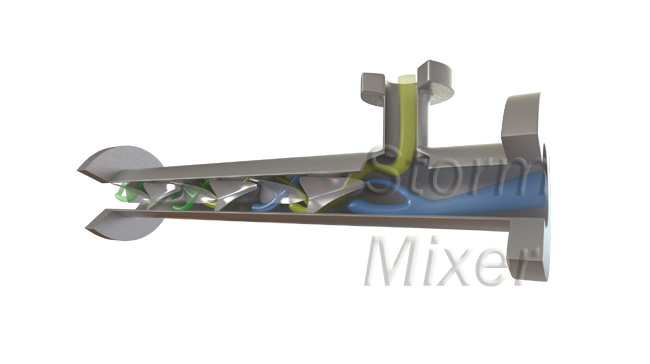

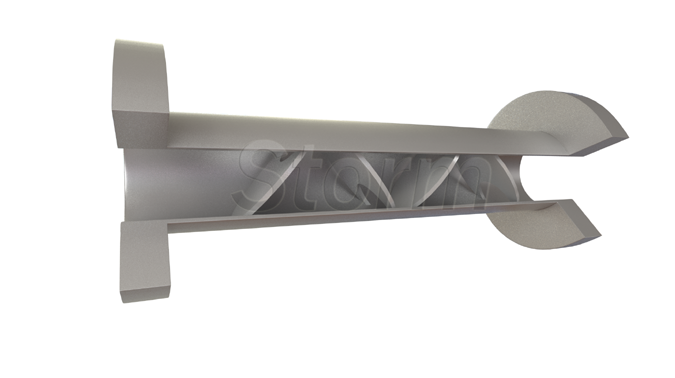

Storm Mixer offers the CX series of static mixers for Crude Oil Custody Transfer applications.

This mixer is designed to lift and mix/disperse the heavier water that can lie at the bottom of a transfer pipeline with the crude oil pipeline so that the quantity of water in your crude oil can be effectively measured.

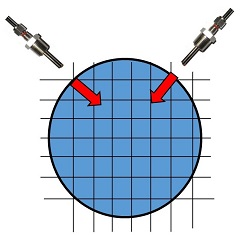

The mixing element is designed to scoop the water from the wall of the pipeline and cause it to mix into small droplets that are evenly dispersed through the entire pipeline diameter. This allows for effective measuring of water content using a non-contact analyzer.

After mixing the oil completely, the final mixing element is additionally designed to eliminate the centrifugal spinning forces that can force water back towards the wall of the pipe. This final mixing element is designed to cancel all rotational forces on the flow preventing a spiraling stream of water from forming back in the pipe before reaching the analyzer.

Typically the analyzer is located 2-4 pipeline diameter downstream of the Custody Transfer Mixer.

This CX series mixer results in highly reliable net crude oil measurements.

As these mixer are designed to meet your requirements, please contact us for more information. Typically they are offered in Carbon Steel, 150# thru 600# ratings. They can be provided with any sampling fittings that you require, including a sampling quill.

Primer exterior coating is standard.

Storm Mixer can offer nearly all of our mixers with a lower pressure drop mixing element.

This mixing element has a pressure drop that is 1/3 to 1/2 the pressure drop of our standard TornadoTM mixing element, while delivering excellent mixing performance.

download the Low Pressure Drop Static Mixer Brochure (800 kb)

download the Low Pressure Drop Static Mixer Brochure (800 kb) ![]()

Diluting Concentrated Sulfuric Acid with a static mixer

For Mixing concentrated sulfuric acid into a large pipe line and reducing possibility of corrosion, we recommend diluting the acid in-line with the pipeline using a small pipe loop

Batch Mixing

Mixing a tank of dilute solution using a static mixer

A common task is to mixing a concentrated solution into a tank in order to create a dilute solution on a batch basis. This can be done accurately and safely using a recirculating loop on the tank.

For making aqua ammonia from anhydrous ammonia, or taking concentrated sulfuric acid and making a batch of diluted acid, this method is superior to others. A hydrometer can be installed in a sight glass and this will allow the operator to manually ensure that the concentration of the dilute batch is accurate.

Using a Static Mixer as a Flash Mixer for Flocculation

A static mixer makes an ideal flash mixer for flocculation processes

There are some specific parameters that will allow for optimum design of these flash mixers.

Flash Mixing using a static mixer

Determing the Mixing Efficiency of a Static Mixer by Measuring the Coefficienct of Variation CoV

Calculating the CoV or mixing efficiency of a static mixer